Going over old ground

Ive recently been doing a few revisions on the layout.

The first was prompted by a failure. It had always irked me a little that the above lamp was a little bit crude and the top wasn’t really the distinctive shape the lights at Round Oak had. Being at the back in a dark corner it wasn’t noticeable enough to invest any time into. However when it recently failed why not kill two birds with one stone?

The first was prompted by a failure. It had always irked me a little that the above lamp was a little bit crude and the top wasn’t really the distinctive shape the lights at Round Oak had. Being at the back in a dark corner it wasn’t noticeable enough to invest any time into. However when it recently failed why not kill two birds with one stone?  So after a bit of tweaking I’m much happier with it now.

So after a bit of tweaking I’m much happier with it now.

Ground Signals. I originally used the MSE kits but I had found a few drawbacks. First thing was A few had took some knocks while cleaning the track. As they use a whitemetal casting for the main body and legs they really didn’t like this at all and were starting to look a bit bent and battered. Secondly as I had fitted lights there wasn’t a lot of room to work and I had just drilled out the lamp housing and shoved a nano LED in there with slightly mixed results.

Ground Signals. I originally used the MSE kits but I had found a few drawbacks. First thing was A few had took some knocks while cleaning the track. As they use a whitemetal casting for the main body and legs they really didn’t like this at all and were starting to look a bit bent and battered. Secondly as I had fitted lights there wasn’t a lot of room to work and I had just drilled out the lamp housing and shoved a nano LED in there with slightly mixed results.

One consequence of this wass more light bled out of the bottom than through the signal despite various attempts to fill the hole

One consequence of this wass more light bled out of the bottom than through the signal despite various attempts to fill the hole

So step in the Palatine models etched kits as a replacement. These are hopefully stronger and being an etch theres more room to position the LED in a better controlled way. I say more room but in 4mm scale ground signals are tiny but because of that even a slight gain is a big help. I modified the kits a little to make them work and drilled a couple of holes for the lights. Results are below

On the subject of signals Ive been playing around with resistors again to try to get the lamps a bit closer to how the real thing looked and less like a modern colour light. I think I’m there now.

Up on the road Ive added a few telegraph poles meaning I think I can call this area finished now.

A revisit to my classic (or is that cliché?) scene. This time a wider verson.

A revisit to my classic (or is that cliché?) scene. This time a wider verson.

Back to wagons – and a correction.

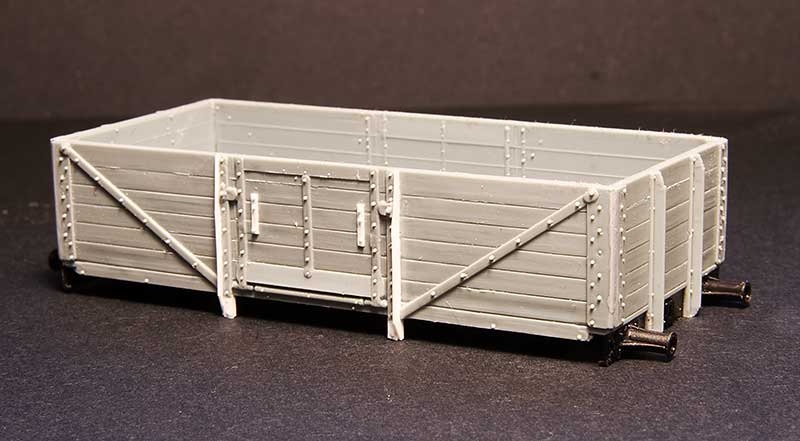

A while ago I did a batch of shock opens including an attempt at an ex-LMS diagram 1983 variant. Justin of Rumney Models noticed that I had used the same ends as the BR version with inset corrugations while the LMS wagon has corrugations that stick out. Something I had completely failed to notice myself. So that wagon had its top lip removed and renumbered back to a BR one. A new kit was brought (well a few actually – saves on postage!) and a second attempt made using cut down spare ends from a Parkside 12t van kit. The BR version is at the back. Theres a few other differences too like the bang plates for the doors, the shape of the panelling on the ends and the braces under the door.

The finished wagon in the company of yet another D2150 13t open.

The finished wagon in the company of yet another D2150 13t open.

The BR wagon has had a Rumney models sheet rail added and been mated with a clasp brake chassis to produce a D1/040 variant. Buffers are from Lanarkshire Models.

The BR wagon has had a Rumney models sheet rail added and been mated with a clasp brake chassis to produce a D1/040 variant. Buffers are from Lanarkshire Models.

Moving on to a couple of hoppers.  First up the Accurascale 24.5t hopper which i picked up cheaply from a private sale on Western Thunder. It came in brown livery and with a certificate saying it was a limited edition number 061 of 500. If this sort of thing matters to you and you have one you will be pleased to know that your model is now even more limited being 1 of 499 (You’re welcome!). It was separated into its component parts (a process that had already started in the box) and the body resprayed. These are not a straight drop in wheels job as the axles used are a little short and theres a boss on the back of the W-iron, much like Lima was doing 40+ years ago. Its not a huge problem though as a few turns of a bearing cutter (I use Ed’s tool) and a little bit of thinning the boss down and off you go. I also cut off the NM pockets.

First up the Accurascale 24.5t hopper which i picked up cheaply from a private sale on Western Thunder. It came in brown livery and with a certificate saying it was a limited edition number 061 of 500. If this sort of thing matters to you and you have one you will be pleased to know that your model is now even more limited being 1 of 499 (You’re welcome!). It was separated into its component parts (a process that had already started in the box) and the body resprayed. These are not a straight drop in wheels job as the axles used are a little short and theres a boss on the back of the W-iron, much like Lima was doing 40+ years ago. Its not a huge problem though as a few turns of a bearing cutter (I use Ed’s tool) and a little bit of thinning the boss down and off you go. I also cut off the NM pockets.

What is a little bit more of an issue is it doesn’t weigh anything, just 21 grammes out of the box. Obviously if you plan to run your wagons loaded no problem but if you want them empty (as did ) then a little bit of trickery is required.

My solution was to make new lower sides from 1mm lead. This brings the wagon up to 50 grammes. If you would like to follow suit I drew up a little cutting template which you can download from here

My solution was to make new lower sides from 1mm lead. This brings the wagon up to 50 grammes. If you would like to follow suit I drew up a little cutting template which you can download from here

Another parkside 21 tonner based on a picture that came up on my facebook feed. (some of the wagons in the post are waiting a delivery of couplings you may notice). Theres often a discussion when these kits crop up that they are difficult to build but they really aren’t. The trick is to assemble a side and end as 2 pairs on a piece of glass with a cutting matt to ensure they are square, let these set fully before assembling the rest of the wagon and theres no problems Any slight gaps between the panels can be filled from the inside using Mr Surfacer 1000 liquid filler.

Another parkside 21 tonner based on a picture that came up on my facebook feed. (some of the wagons in the post are waiting a delivery of couplings you may notice). Theres often a discussion when these kits crop up that they are difficult to build but they really aren’t. The trick is to assemble a side and end as 2 pairs on a piece of glass with a cutting matt to ensure they are square, let these set fully before assembling the rest of the wagon and theres no problems Any slight gaps between the panels can be filled from the inside using Mr Surfacer 1000 liquid filler.

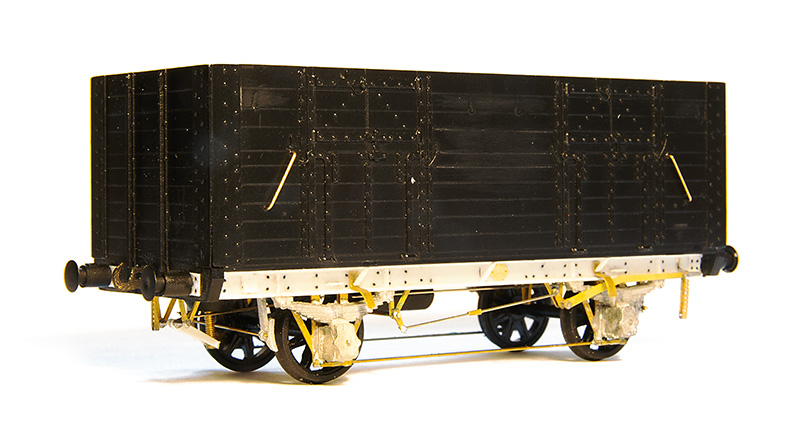

Now a few oddballs – this is an ex L&Y diagram 81 loco coal wagon from the old MAJ models kit. The kit is supplied with a wooden chassis which is correct for the earlier wagons but i wanted the later one so only used the body. The brake gear on these were a little weird to say the least

Now a few oddballs – this is an ex L&Y diagram 81 loco coal wagon from the old MAJ models kit. The kit is supplied with a wooden chassis which is correct for the earlier wagons but i wanted the later one so only used the body. The brake gear on these were a little weird to say the least

The plan is to have a short train of condemned wagons that is delivered to the yard as a trip working from Bescot. These are then to be collected by one of the Round Oak locos to be taken away for scrapping and the metal bits melted down in the furnaces. This is basically what happened and quite a few locos met their fate this way in real life. Unlike some of the more famous railway scrap yards stuff didn’t hand around for long so nothing from my scrap train will have any hope of reprieve sadly. The condemned markings are from Railtec,

The plan is to have a short train of condemned wagons that is delivered to the yard as a trip working from Bescot. These are then to be collected by one of the Round Oak locos to be taken away for scrapping and the metal bits melted down in the furnaces. This is basically what happened and quite a few locos met their fate this way in real life. Unlike some of the more famous railway scrap yards stuff didn’t hand around for long so nothing from my scrap train will have any hope of reprieve sadly. The condemned markings are from Railtec,

Another victim this time a GWR diagram 04 open from the cooper craft kit. Like another Coopercraft kit I’ve built this has the bearing holes mounted too low meaning that the wagon looked like it was on stilts. This one has slightly odd brake gear as well. You can just make out the old GW branding.

Another victim this time a GWR diagram 04 open from the cooper craft kit. Like another Coopercraft kit I’ve built this has the bearing holes mounted too low meaning that the wagon looked like it was on stilts. This one has slightly odd brake gear as well. You can just make out the old GW branding.

The LMS traction truck has finally been mated with its load.

The LMS traction truck has finally been mated with its load.

Also based on a picture that cropped upon my facebook feed is this Borail from the Cambrian kit. Making the load was far from the most interesting task I’ve ever done I can tell you and despite it being essentially hollow this wagon still hovered up 5 meters of rail!

Also based on a picture that cropped upon my facebook feed is this Borail from the Cambrian kit. Making the load was far from the most interesting task I’ve ever done I can tell you and despite it being essentially hollow this wagon still hovered up 5 meters of rail!

Its all gone a bit Eastern Region

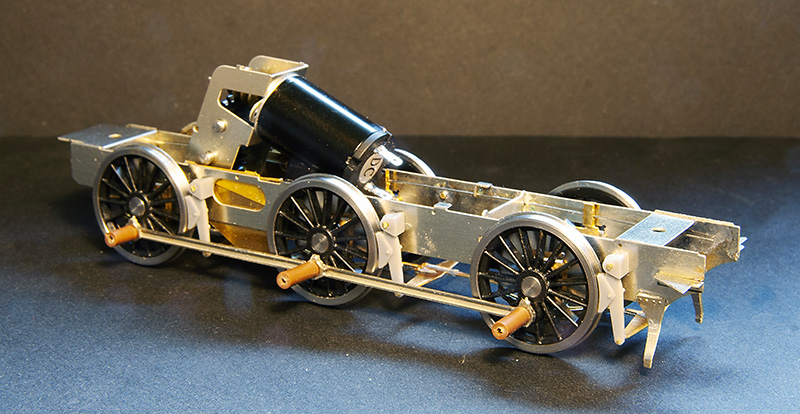

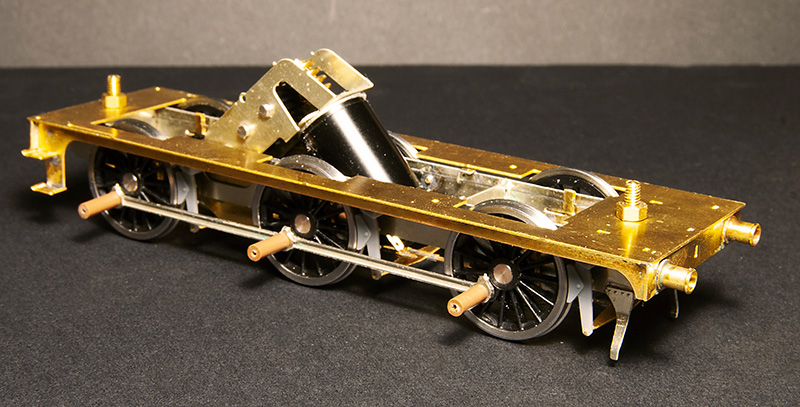

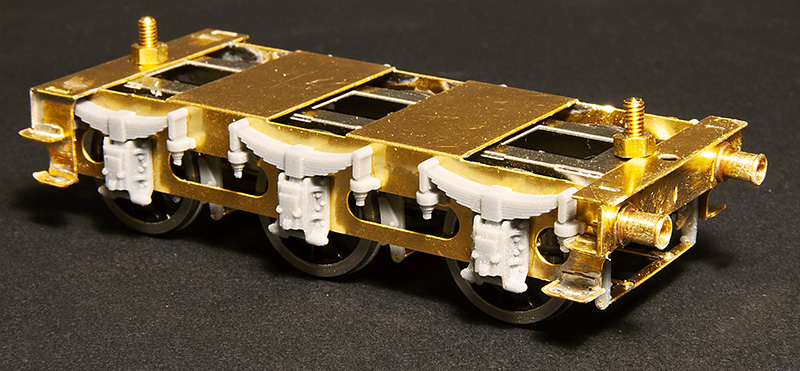

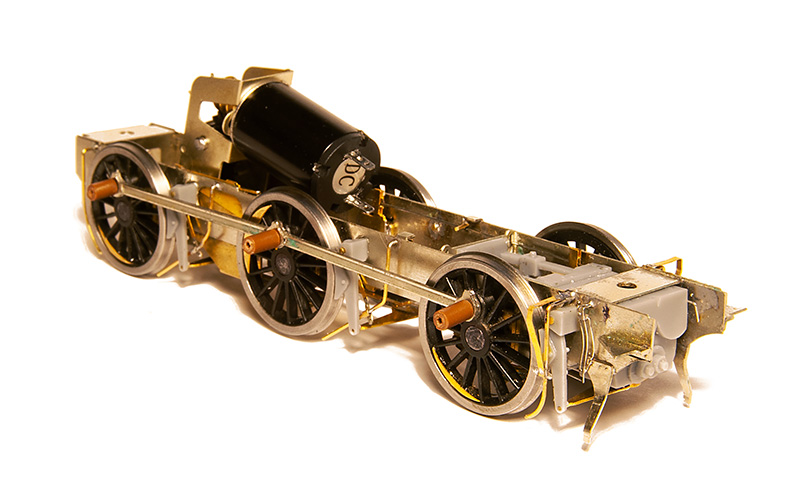

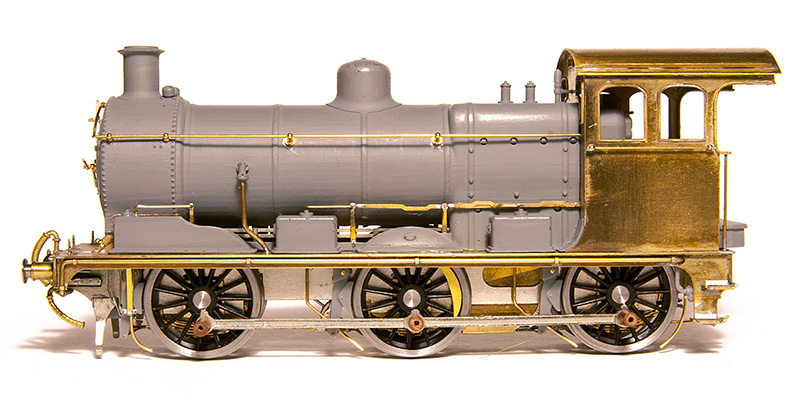

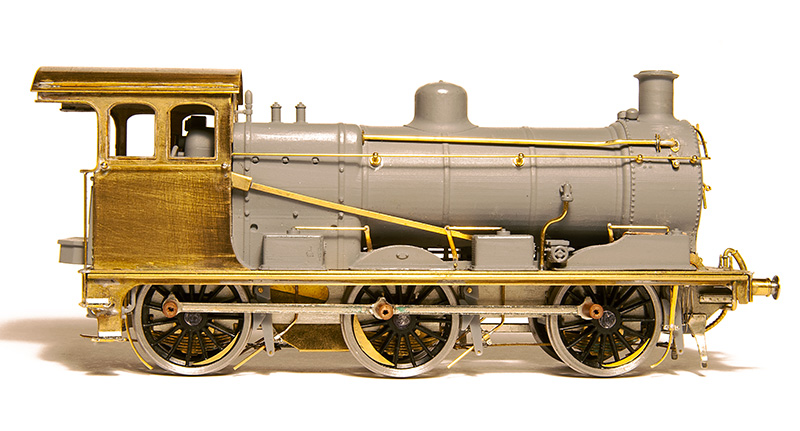

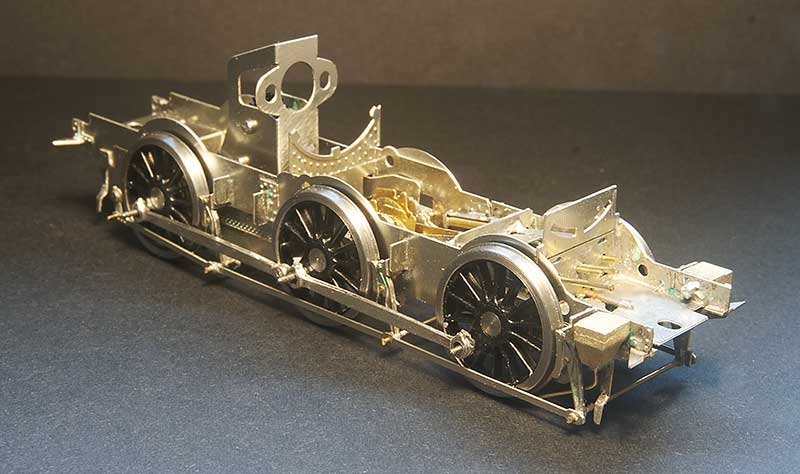

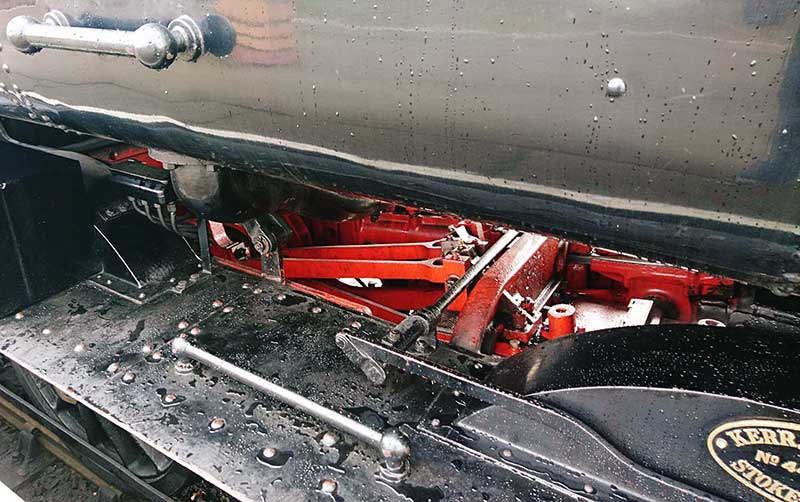

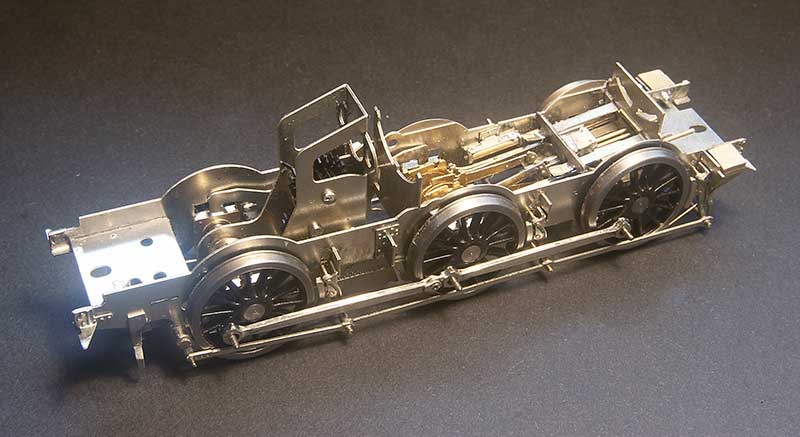

Over the last week or so Ive embarked on another test build for Brassmasters. This time a J17 kit thats been designed by David Barham. Its not really any use for Brettell Road but it would fit North Elmham (which I have been know to help out with).

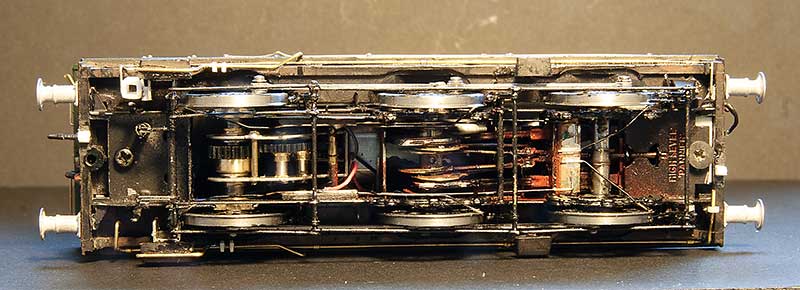

The basic chassis build with a High level Loadhauler gearbox. The loco and tender use CSBs throughout. The kit will be supplied with both printed and etched brake shoes.

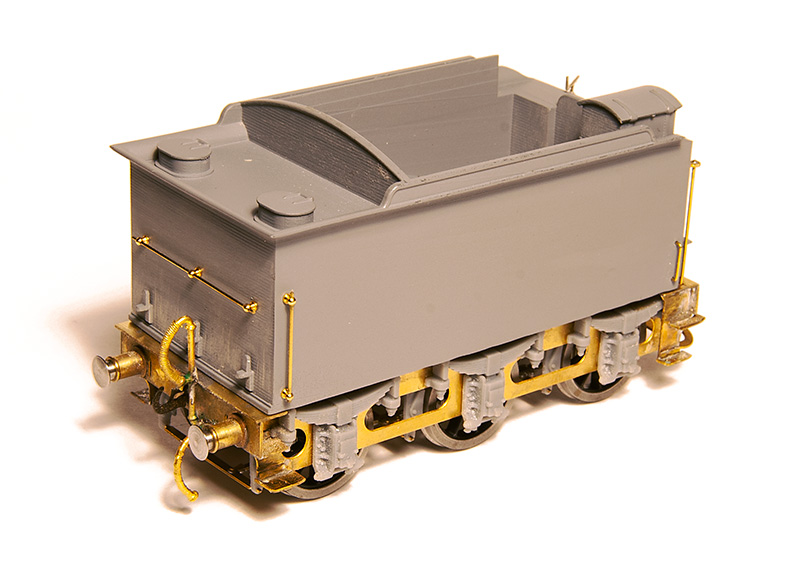

The tender subframe – Again with options on the brake shoes.

The tender subframe – Again with options on the brake shoes.

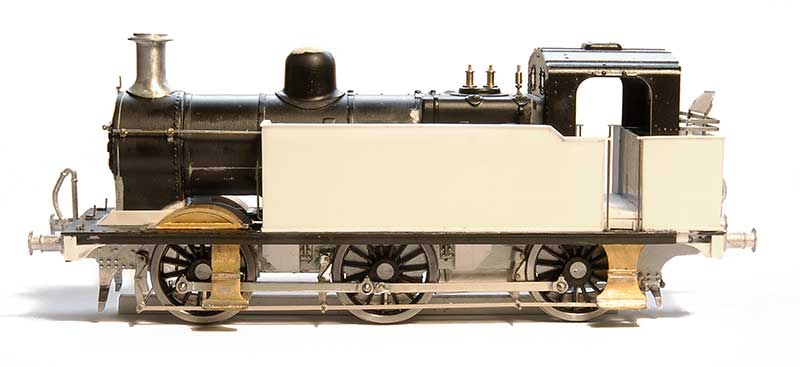

Chassis and footplate.

Chassis and footplate.

Tender with its outer frame.

Tender with its outer frame.

The cab

The cab

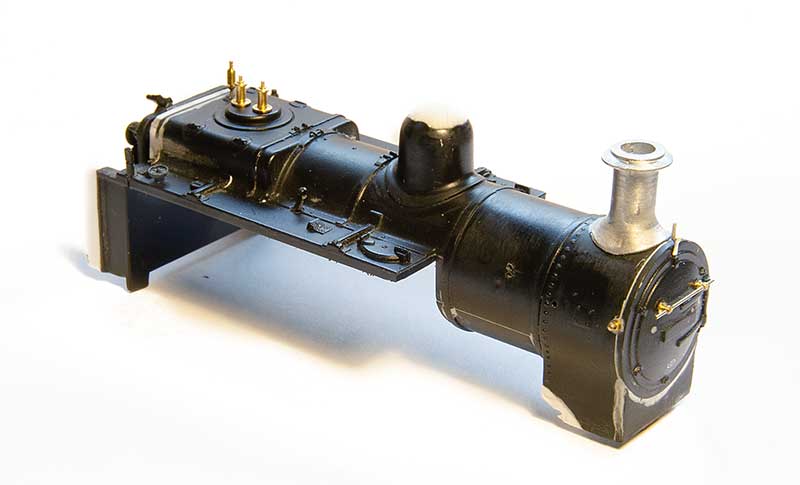

Pretty much everything above the footplate and forward of the cab is catered for by a 3D print. Here I’ve made a start on the basic detailing

Pretty much everything above the footplate and forward of the cab is catered for by a 3D print. Here I’ve made a start on the basic detailing

The tender body, like the loco, is a 3D print.

The tender body, like the loco, is a 3D print.

The detailed up chassis

The finished loco – More pictures below. This has been a pleasure to put together.

shuffling and testing.

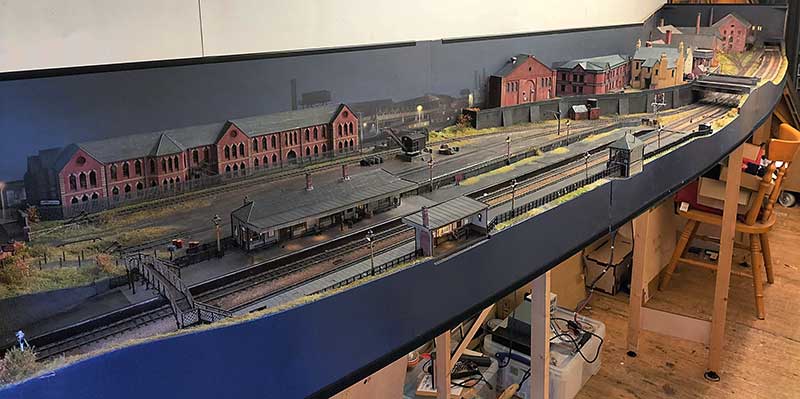

A bit of re-jigging of the shed means I have been able to put all of the scenic boards for Brettell Road up together. Its 5 months since the Cradley show – Time flies doesn’t it?

Theres a few things to fix after the show. A couple of the points needed a check over as they weren’t totally reliable. I also found 2 dead sections that hadn’t shown up during the show so I fixed those too.  The lights on the upper floor of this building failed before the show but after the building had been planted onto the layout. It was too close to the show to fix it before so this is something to look at now I have time. I also want to add a few yard lights and sort out the telegraph poles on the layout because as they stand now they don’t make a huge amount of sense.

The lights on the upper floor of this building failed before the show but after the building had been planted onto the layout. It was too close to the show to fix it before so this is something to look at now I have time. I also want to add a few yard lights and sort out the telegraph poles on the layout because as they stand now they don’t make a huge amount of sense.

The other thing to fix was the route setting on the main lines. Signalling purists are advised to look away now! Before the track and signals were all operated separately via the throttles with only the yard set up as a route. (My Digitrax system allows me to program routes into it.) So thats been changed for operator convenience so that throwing a signal sets the route as well. I know the route should be set then the signal pulled rather than this way round. You can set the signals to danger on their own but in case you forget the routes will set all the other signals to danger for you anyway. I hoping this will be pretty simple to use.

Since the show I have a small stockpile of new rolling stock to be tested. The rule is all stock must go everywhere without falling off, even though in this image only the middle road of wagons will go into the yard at shows. Of this little lot only 4 wagons were rejected and returned to ‘works’ for some fettling. These 4 have now been passed too.

Since the show I have a small stockpile of new rolling stock to be tested. The rule is all stock must go everywhere without falling off, even though in this image only the middle road of wagons will go into the yard at shows. Of this little lot only 4 wagons were rejected and returned to ‘works’ for some fettling. These 4 have now been passed too.

Below, just some more traditional layout style pictures.

Clay and sheets

One working that passed through the real Brettell Lane and kind of fascinated me was the St Blazey to Etruria china clay working. This service ran for years and was somewhat erratic in the paths it took. Usually going via Worcester, Stourbrige then Dudley before heading off to Bescot. Or it could go right at Stourbridge via Old Hill and (I think) Soho Junction. These routes avoided the Lickey but I’ve seen pictures of it going that way too in later years. When I was at University in Stoke it would often turn up at lunch time behind a pair of class 37s although it did switch to a class 60 in the time I was there.

So to have a clay train on Brettell road makes sense as a through service. I like the classic diagram 1/051 clay opens with their sort of cute, baby open wagon look about them. A little bit of rewriting of history is needed though as they tended to stay in Cornwall and not venture out to the Midlands. Brettell Road is set before the introduction of the clayliner service so my justification is that BR was trialing things out to see how they would work and thats good enough for me.

Ratio make a nice little kit for these and I was fortunate to find someone selling a box of 7 on Ebay for what basically worked out as a fiver each. The bodies go together well with a little bit of modification to make the ends fit. The kit features a somewhat crude attempt at a roller bearing and the brake levers are quite poor. It also includes cast buffers that aren’t all that great. So the bearings were replaced with MJT ones although my research showed oil axleboxes to be more common anyway. Brake levers are from the Mainly Trains etch, door bangers from Rumney models and buffers from Lanarkshire models. I did one as a test then built the other 6 as a batch.

Before I move onto the sheets a bit about the weathering. I followed my usual approach of a wash of dark grime followed by a spray of AK interactive dark mud. This was then all sealed with Klear before AK interactive white ink was used (in various levels of dilution) to give an overall effect of clay staining. You don’t want a fully weathered wagon at this stage, try to think of it as you are aiming for about half the effect you ultimately want.

Previously when I have done wagon sheets I make the sheet up with the ropes attached to it and then attach it to the wagon. This is a bit of a faff and sometimes the glue holding the rope to the sheet can give an odd effect so I approached this a bit differently. Roping of wagon sheets is a whole topic on its own and I will leave that too someone who has properly studied the subject but I just looked at pictures and coped what I saw. So the first stage is to attach the ropes (cotton) to the wagon – Tying it on at the visible ends and gluing to the wagon top with Loctite

This was then tided up by first sealing the knots with Zap Pink superglue. Theres no huge reason to trim the ropes inside the wagon but it pays to just keep things neat so they don’t get in the way later.

This was then tided up by first sealing the knots with Zap Pink superglue. Theres no huge reason to trim the ropes inside the wagon but it pays to just keep things neat so they don’t get in the way later.

As mentioned before the sheet is made from black latex gloves (actually nitrile) and mine are a brand called Supertouch. They are a bit awkward to cut as the material tends to snag on the scalpel blade even if the blade is brand new. A method I found to work best is to stretch the glove over a bit of cardboard, make a template and to cut it using the handle end of the blade not the pointy end, pushing the scalpel away from you to cut. I don’t know why this makes a difference but it does! As i’ve mentioned in the past the material is black on the outside and a dark grey on the inside. I use the black side as its depicting wet conditions but the grey is good for a nice sunny day layout.

The sheet is then positioned in place, not forgetting to add weight inside the wagon and bulking it up with a bit of tissue first before gluing to the wagon tops in 6 places, about where the ropes are. Use Loctite and start in the middle (it sets very quickly) and remember to pull it taught as you glue the outer sides. This is one of those things were you probably need a bit of variation but you don’t want to force it. I find if I try to be as neat as I can, I’m not all that neat really and I get the variation by default.

Next stage is to glue the sides of the sheet to the ropes, again with loctite and again puling the sheet taught. I found holding it in place for 10 seconds was all you need. It pays to glue the sheet the side of the wagon at the ends at this stage

On to the ends. Another drop of super glue on the top and the sheet can be glued in place. The corners can be folded and secured in place and the last set of ropes glued into the sheet itself.

The last ropes tied into place and tidied up.

The final weathering, back to the white ink (sprayed this time) with some additional grease stains on the underframe.

To break up the rake a bit I added a few 10ft wheelbase opens too. These are actually way more typical of the actual wagons used in the clayliners. The ex LMS Diagram 2150 I’ve featured before a few posts ago.

To break up the rake a bit I added a few 10ft wheelbase opens too. These are actually way more typical of the actual wagons used in the clayliners. The ex LMS Diagram 2150 I’ve featured before a few posts ago.

Likewise the ex LNE diagram 210 (although not this specific model)

A new wagon type for me is the ex LNE diagram 185. This was constructed from the body of the Cambrian kit C81 for the LNER 12ton 6 plank Open Wagon, With a Parkside 10ft underframe. Theres a few tweaks needed to the body as can be seen and theres an additional top support across the top of the door which is worth adding assuming you aren’t going to cover it over with a sheet that is!

Just need an enterprising transfer manufacturer to produce some sheet markings now.

More shockingly mundane stuff

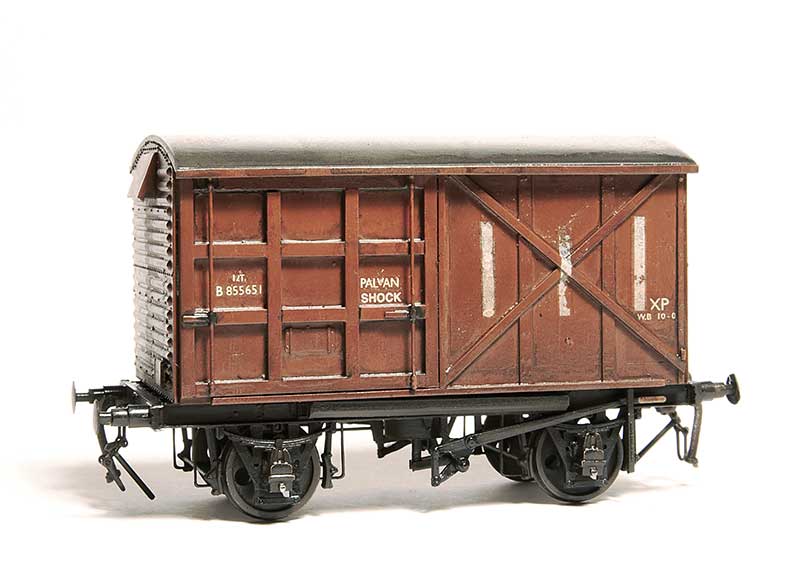

As a follow on to the last post – more every-day wagons have rolled off the workbench. This time it’s a quartet of shock wagons.

Starting with the basics – Diagram 1/040 shock open from the Parkside kit. Built pretty much as supplied with the addition of a Rumney Models tarpaulin bar and a sheet from my now standard black latex glove.

Next ex LMS diagram 1983 from the same kit as above with the additional top lip on the ends and buffers from Lanarkshire models. You cant see it in the pic but I replaced the floor with scribed lead sheet.

EDIT – More info has come to light on these wagons and this one is wrong – see https://p4newstreet.com/back-to-wagons-and-a-correction/

A smidge more involved is this Diagram 1/038 shock open from the parkside kit for the standard (not shock) wagon. I shortened the sides by cutting sections out next to the middle section and mounted them on a new floor as the prototype wagons had a visible lip around the bottom.

Finally a diagram 1/219 shock palvan. A bit more involved again as I could use spare ends and a roof from Parkside standard 12t vans but the sides needed to be made from scratch. The chassis is the Red Panda kit.

Just some mundane stuff.

Just one of those every day, run of the mill style posts this time but with a few little tweaks to appease the wagon buffs.

Starting with the Parkside kit for the LNER 21t riveted coal hopper. Built pretty much as instructed but I did change the side stanchion plates for 10 thou plasticard as the ones in the kit were a bit chunky.

The spare brakes that came with the above kit were used to correct the brakes on my prototype 24.5t hopper I’ve featured before.

The spare brakes that came with the above kit were used to correct the brakes on my prototype 24.5t hopper I’ve featured before.

The humble D2150 13t open from the Parkside kit. The only real visual difference between these and the BR build is the small lip on the ends. A bit of 10×20 thou mictrostrip sorted that.

Ex LNER Diagram 210 adapted from the parkside kit for the Dia 1/120 wagon. The side stanchion were slightly reshaped as were the buffer beams while the chassis was replaced with spares from my scrap box.

Another bog standard affair, the D2039 ex LMS 12t van. This one was built from the Ratio kit with the addiction of the Rumney Models LMS van detailing etch (B105). It features the 3 part end for a super subtle bit of variety.

Finally something a little more involved. Before and after of the sides for a D2103 12t van using the parkside fruit van as a start point. The ends were scratchbuilt.

The good old Mainline LMS BG

The subject this time is this…

… the good old Mainline LMS BG. A great model for its time but not without room for a little bit of TLC. There is an error here that once you see it you cant un-see and that is that the underframe is too wide by 2mm. Ive talked in the past about looking at dimensional errors as a percentage. 2mm off over the width of a coach is a much larger percentage than 2mm over its length but theres an additional factor in play here and that is relationships. If the whole model was 2mm to wide you might (but probably wouldn’t) get away with it but when only part of it is, it just looks weird. Let’s be realistic here we are talking about 1mm per side but that 1mm means the edges of the solebar framing sticks out from the bottom of the body rather than tucking under it. Also the footsteps don’t line up properly but thats a minor thing.

So the options then. You could just replace the underframe with a Comet one but at the time they were out of stock and the trussing is a flat etch so no real improvement over the one already there. Or you could slice 2mm out of the centre of the floor and glue it back together. The issue with this is I don’t think the trussing itself is over width. To me the simplest solution was to make a new floor from plasticard (29.5mm x 196mm) and transplant the trussing from the mainline model. The new solebars are 4mm channel from evergreen.

So heres the model had already done on its new underframe. The bogies are Brassmasters with the original sideframes attached. Buffers have been replaced with more accurate ones from Lanarkshire models.

So heres the model had already done on its new underframe. The bogies are Brassmasters with the original sideframes attached. Buffers have been replaced with more accurate ones from Lanarkshire models.

As is usually the way for me I got a little carried away. Why build one new floor when you can build several? Theres a few subtle differences here such as the roof vents and footsteps.

As is usually the way for me I got a little carried away. Why build one new floor when you can build several? Theres a few subtle differences here such as the roof vents and footsteps.

As with any grouping of things there tends to be one member thats a little bit weirder than the others and this is it. The diagram 1715 version. OK it looks kind of the same but the qay it was build was quite different and actually much more like the much later BR Mk2 in that the body was where all the strength is and it didn’t need a traditional underframe. The solebars themselves are also different in that the outer face is solid. Other variations are the positioning of the roof vents, bodyside beading (which comes in a whole load of variations on these coaches anyway), the extra rain strips and the full length footboards

This is the more normal side. Note the dynamo is at the opposite end to the more standard versions.

This is the more normal side. Note the dynamo is at the opposite end to the more standard versions.

The other side is decidedly more odd with basically next to nothing there. It almost looks like the model hasn’t been finished. Note also the steps on the bogie.

The other side is decidedly more odd with basically next to nothing there. It almost looks like the model hasn’t been finished. Note also the steps on the bogie.

Just a quick note to thank Mark Tatlow and Graham Speechley for their help locating images of the diagram 1715 version.

Back to business as usual

So back to business as usual then.

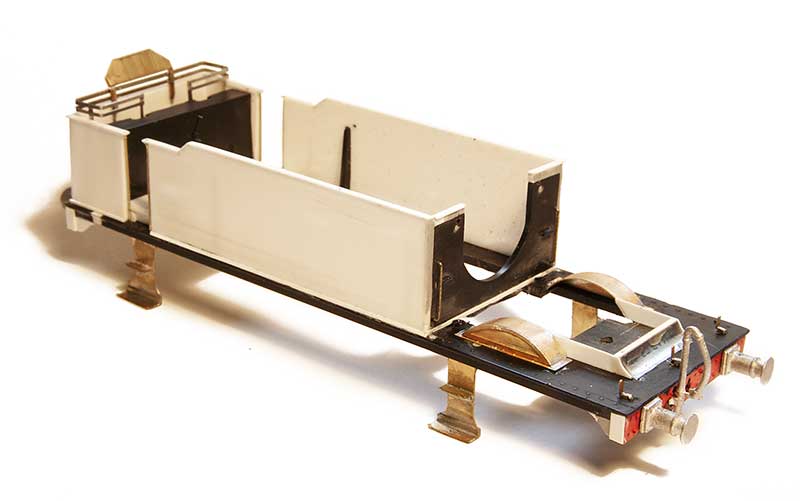

This is an ex LMS 12 ton traction truck which has recently been released by 247 Developments. The kit is a 3d print which is supplied as a body with solebars, W irons, brake gear and white metal buffers. The body was a little bit distorted (kinda like a spoon shape) but popping it in very hot water and weighting it while it cooled seemed to take most of the distortion out. The back of the frames needed thinning for p4 wheels to fit (I believe the kit has been changed to rectify this now). I replaced the sides with microstrip as they were a little uneven and added the safety loops and tie down shackles that were missing from the print. The supplied buffers were a little odd so these are Accurascale ones. Just need to do a load for it now.

On Brettell Road I have mostly used cast white metal vacuum pipes. Generally these have been fine but I have had some of the bufferbeam mounted ones break as they are slightly vulnerable. David Roome has now produced some 3d printed ones that are rubbery and a lot less susceptible to knocks. Im not replacing them on all of my wagons just as and when a white metal one gets broken.

On Brettell Road I have mostly used cast white metal vacuum pipes. Generally these have been fine but I have had some of the bufferbeam mounted ones break as they are slightly vulnerable. David Roome has now produced some 3d printed ones that are rubbery and a lot less susceptible to knocks. Im not replacing them on all of my wagons just as and when a white metal one gets broken.

Links

Cradley Show – Epilogue

My friend Tim has put together a short video of the layout from Saturday. It was late ish in the day and being in front of a window the layout was back lit so didn’t really get the full effect I was after. (Note to exhibitions managers – I actually want the dark bit of the hall no one else does!!) However it does show up the wet effects quite nicely. I need to be a little more fastidious with the dusting in the future.

Cradley Show 2023

Yesterday Brettell Road made its return to the exhibition scene in its extended form. The show went very well I thought and we all enjoyed ourselves. Theres a snagging list for me to work through, of course, but nothing major. The layout seemed very well received and we were honoured to be awarded the Frank Collins Award for best layout in show as voted for by the Cradley Heath MRC committee. Somewhat poignant for me as Frank had assisted me with info for the model of the Round Oak admin building before he passed away. I like to think he would have approved of my efforts. The kids seemed to enjoy themselves looking for the cats on the layout and and the strategically hidden lego Batman that the club provided.

Quick thanks to my operating team and the members of the CHMRC for their efforts.

(Pic ©Tim Horn)

Finishing touches

With a little over a month to go before Brettell Road is back on the road*, I’ve been finishing a few things off.

The last backscene is now in place so the road in the middle of the layout now gives the impression it goes somewhere. The Leyland Steer seems to have lost its licence plate somewhere.

The last backscene is now in place so the road in the middle of the layout now gives the impression it goes somewhere. The Leyland Steer seems to have lost its licence plate somewhere.

The little back yard on board 2 is done – I wanted a used but not particularly looked after feel.

The little back yard on board 2 is done – I wanted a used but not particularly looked after feel.

I realised I’ve not actually taken any images of this building in its finished state before now.

I realised I’ve not actually taken any images of this building in its finished state before now.

Princess Margaret heads back to the Wallows for the evening.

Princess Margaret heads back to the Wallows for the evening.

GWR railcar catches the last of the sun as it heads off to Dudley.

GWR railcar catches the last of the sun as it heads off to Dudley.

* The show is a local one on the 7th October. Click here for more info.

Back scenes done (well most of them anyway)

My Back scenes have been printed onto self adhesive vinyl and most of them mounted to the boards. Just the last one still to do. I used a local company who kindly did a couple of test prints so i could tweak the colours. Anyone local to Stourbridge area who are after something similar I can highly recommend them – SAC Graphics

My Back scenes have been printed onto self adhesive vinyl and most of them mounted to the boards. Just the last one still to do. I used a local company who kindly did a couple of test prints so i could tweak the colours. Anyone local to Stourbridge area who are after something similar I can highly recommend them – SAC Graphics

Below is how it looks in something close to the intended light.

Haven’t done a bit of photoshopery for a while but i found a pic of a Deeley tank in a cloud of steam and thought I’d emulate it

simply back

Today, 21st June 2023 marks a small but significant date in the life of Brettell Road, in that it’s exactly 2 years since Tim and I first cut wood for the 2 new baseboards. I think it fair to say that a reasonable amount of modelling water has flowed under that particular bridge since that day and I’m now drawing in to the layouts final destination somewhat.

Drawing being the word as the big thing thats always been missing from any pictures of the new boards is the backscene. Long time readers may recall that this is an area of the layout that I have revisited on more than one occasion and, with every intention of this being the last time, I find myself deciding to get this particular subject closed off once and for all.

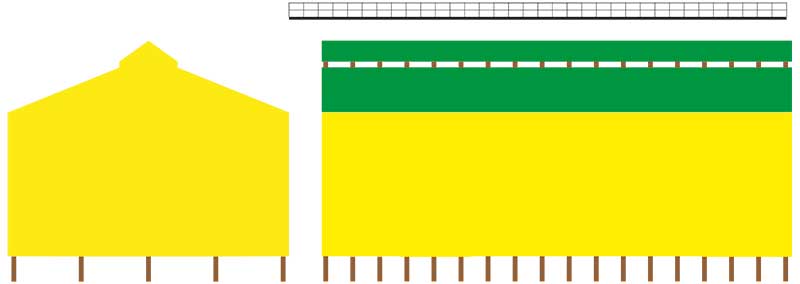

The method

The method I use is like modelling but in a 2 dimensional world rather than 3. Starting with drawing up the basic structure in much the same way as I do the modelled buildings.

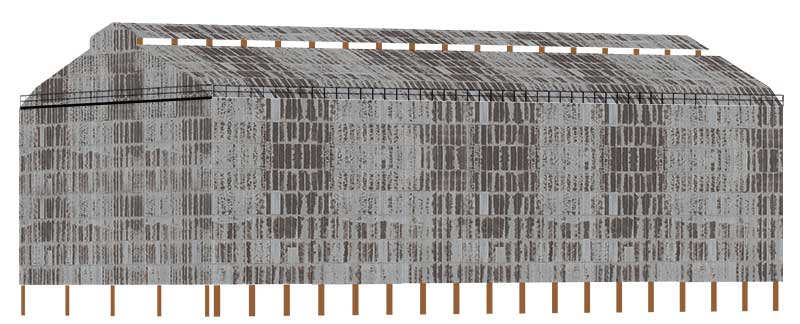

Above is the basic drawing of a typical industrial shed. Think of it like a kit of parts. This is done in Adobe Illustrator and the rather bright colours are simply so that they are easily selectable at the next stage.

Above is the basic drawing of a typical industrial shed. Think of it like a kit of parts. This is done in Adobe Illustrator and the rather bright colours are simply so that they are easily selectable at the next stage.

Which is to transfer the basic drawing to Photoshop where Scalescenes textures are overlaid and the bits ‘assembled’ into something resembling a basic 3d building. You will note theres no shading and no perspective yet.

Which is to transfer the basic drawing to Photoshop where Scalescenes textures are overlaid and the bits ‘assembled’ into something resembling a basic 3d building. You will note theres no shading and no perspective yet.  A different building showing some shading and some perspective. The image is still made up of separate parts in a folder so that I can fine tune it once applied to the finished backscene.

A different building showing some shading and some perspective. The image is still made up of separate parts in a folder so that I can fine tune it once applied to the finished backscene.

Of which this is the end board for the left of the layout. Some consideration, such as the metal fence, needs to be made for elements of the layout that will cross from the 3d world to the 2d one. The line the railway takes, under the bridge on the left is hinted at by the arrangement of the trees.

Of which this is the end board for the left of the layout. Some consideration, such as the metal fence, needs to be made for elements of the layout that will cross from the 3d world to the 2d one. The line the railway takes, under the bridge on the left is hinted at by the arrangement of the trees.

This is the view of the bottom of the hill on the left. Again the wall and the building on the right of the image are intended to match up with the 3d model.

This is the view of the bottom of the hill on the left. Again the wall and the building on the right of the image are intended to match up with the 3d model.

And finally the middle bit of the 2 new boards. Based on images of the real Round Oak. Of course the point of all this is that its there but not really all that noticeable at the same time.

And finally the middle bit of the 2 new boards. Based on images of the real Round Oak. Of course the point of all this is that its there but not really all that noticeable at the same time.

Revised fiddleyard

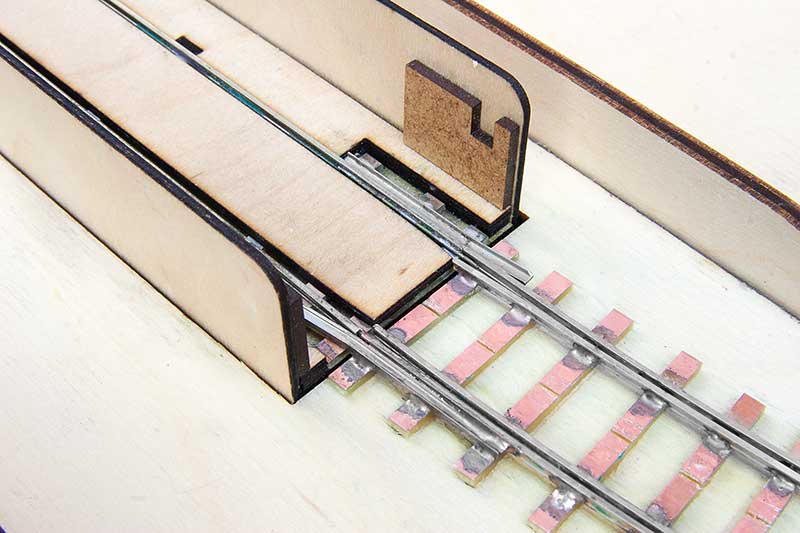

Ive mentioned before that enlarging Brettell Road would mean I need to build new fiddleyards. The reason for this is the way the cassette system worked was to have a recess in the board which given that the layout is now 2 tracks meant the old ones couldn’t really be made to fit. I also took the opportunity to make some improvements and the result can be seen above.

Ive mentioned before that enlarging Brettell Road would mean I need to build new fiddleyards. The reason for this is the way the cassette system worked was to have a recess in the board which given that the layout is now 2 tracks meant the old ones couldn’t really be made to fit. I also took the opportunity to make some improvements and the result can be seen above.

The boards are 6 inches longer and this time I’ve included a little barrier on the near side edge to stop anything falling off It never did but it was something that bothered me.  View from the front. I decided that the Round Oak industrials running on the mainline was a no-no, so now they will appear from the right of the layout behind the warehouse. As the mainline drops away this means that i needed a different level for this bit.

View from the front. I decided that the Round Oak industrials running on the mainline was a no-no, so now they will appear from the right of the layout behind the warehouse. As the mainline drops away this means that i needed a different level for this bit.

With the cassettes I have also made some improvements. The originals use 9mm ply which as it was unsupported did bend somewhat. I now have 3 sizes instead of the original 2. A short one for locos, A medium one for units and a long one for coaches/wagons. I have made the long and loco ones reversible but I only expect to reverse some of the locos.

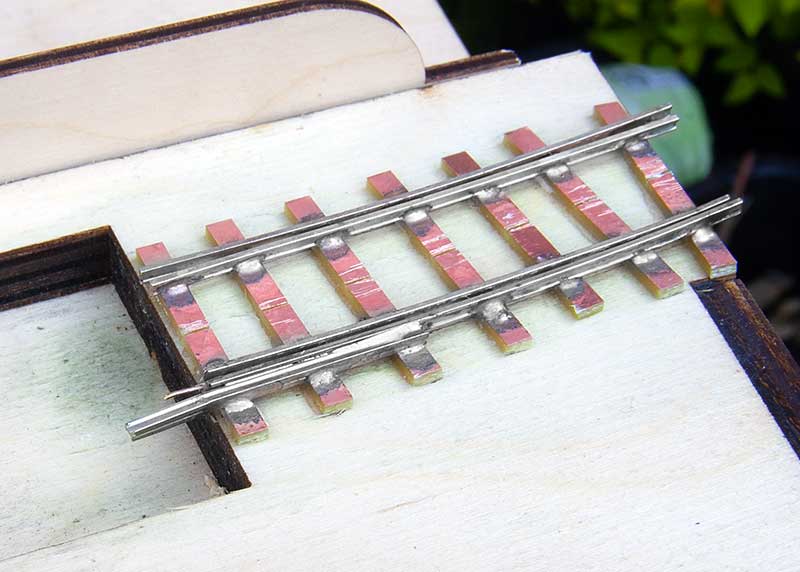

Pictured are the loco and unit versions. The base is 9mm MDF this time.

Pictured are the loco and unit versions. The base is 9mm MDF this time.

The little bits on the inner ends are for rudimentary buffer stops. This stops the trains running off the end but also adds a little security when lifting the cassettes so that nothing rolls off.

The little bits on the inner ends are for rudimentary buffer stops. This stops the trains running off the end but also adds a little security when lifting the cassettes so that nothing rolls off.

The way they connect is a tweak on my original design of using a bit of flat bottom rail on its side – positioned in the web of the running rail for alignment and electrical connection. Originally these were both sides and the rails on the cassettes were angled outwards a little for a good fit. Making the loco cassettes reversible main this wouldn’t work and so a small bit of 0.6 straight wire is soldered to the inside of the web to help with alignment.

The way they connect is a tweak on my original design of using a bit of flat bottom rail on its side – positioned in the web of the running rail for alignment and electrical connection. Originally these were both sides and the rails on the cassettes were angled outwards a little for a good fit. Making the loco cassettes reversible main this wouldn’t work and so a small bit of 0.6 straight wire is soldered to the inside of the web to help with alignment.

You may be wondering what the little blocks are for in the first 2 pictures.

Taking a hint from Amlwch (a layout i used to help out with) I decided to make the storage of the cassettes integrated with the fiddleyards. This one will store the locos and units, the other one the long cassettes. Most of the braces slot in place meaning I can lock in place 8 unit cassettes with just 3 bolts and 16 loco cassettes with just 2. The less time spent faffing about at an exhibition the better!

Taking a hint from Amlwch (a layout i used to help out with) I decided to make the storage of the cassettes integrated with the fiddleyards. This one will store the locos and units, the other one the long cassettes. Most of the braces slot in place meaning I can lock in place 8 unit cassettes with just 3 bolts and 16 loco cassettes with just 2. The less time spent faffing about at an exhibition the better!

Thanks as always to Tim for allowing me to hijack his laser cutters.

Heavyweights done

Just a super short post this time. The wagons featured last time are done and can be released into the wild.

Is it just me or do metal kits always just seem a bit ‘meh’ once they are painted?

A couple of WIP heavyweights and breaking the golden rule.

When my friend Tom kindly gave me the Ks kit for the Coral glass wagon (featured earlier) he also gave me another Ks kit for the 24.5t coal hopper. Further investigation showed that this was a kit that was based on the prototype B333000 which was not really like the production ones in that the ends were different. I suppose back in the day this was your only option however now you can buy 24.5t hoppers ready to run this strange little oddity might have a little value as something different from what everyone else is doing.

B333000 was one of 2 prototypes and was built at Shildon. The other B333001 was built at Ashford and it seems to heave been this latter example that influenced the production run. I believe B333000 was later used for experimentation of the automated doors used for MGR trains but photos of it are rare as hens teeth. Simon Bendall kindly supplied the only picture I had to work from.

So, breaking a golden rule I have had to make educated guesses about some of the details of this wagon. The underframe in Simons picture is very dark and looked to have been modified in some way. It was claimed the Shildon design was basically a taller 21 ton hopper and the lack of outer discharge doors kind of backs that up. So getting hold of a parkside 21t kit to use as a guide I set to work.

The hopper had some chunky mouldings on the inside of the corners that gave quite a positive location. But as I wanted it to be empty they had to go. I replaced the W Irons with Bill Bedford sprung ones (from my nearly depleted stocks) and Wizard model axle boxes. These were soldered in place as supplied and when I was happy everything was square the centre of the w irons was cut away to give an open floor. The end platforms were replaced with a bit of brass as the moulded ones sat on top of the solebars and were too thick. The kit had no hopper doors so these were made from plasticard using a parkside 21t hopper kit as a guide.

The finished wagon (well almost finished – I haven’t added the door mechanism handles yet) is a bit of a heavyweight in that its 78 grammes. About 50% more than my usual target of 50g.

The parkside kit built up. This is the opposite of the Ks kit as while i added some lead overlays to the inside lower hopper its a tad light at only 38g.

Moving away from hoppers I’ve also finished of the construction phase of this…

A David Geen milk tank which I was told by the man himself when I brought it was the last one! This uses a Rumney models chassis and has, to be honest, been a bit of slow burner. Its one of those kits that I just seemed to struggle to get any enthusiasm for but I’m pleased with it now it’s done. I thought the hopper was heavy but this weighs in at 88 grammes!

Back to the beginning (and then a bit more too) Part 2

My 2441 tank is now done. Heres some images

I will need to straighten that station lamp. It’s amazing how things are so obvious in a photo but equally so invisible to the naked eye!

I will need to straighten that station lamp. It’s amazing how things are so obvious in a photo but equally so invisible to the naked eye!

Crew by Modelu which is pretty much standard these days

Crew by Modelu which is pretty much standard these days

Lurking

Back to the beginning (and then a bit more too)

The Great British Locomotives Jinty. The model that started this whole diversion into the late 50s era. When they first appeared (as part of a magazine series) they were so cheap that I brought a second one just so I could do a before and after picture.

The Great British Locomotives Jinty. The model that started this whole diversion into the late 50s era. When they first appeared (as part of a magazine series) they were so cheap that I brought a second one just so I could do a before and after picture.

Recently I dug it out but I didn’t want to just do another Jinty so my focus has been on its predecessor, the Johnson designed Midland 2441 class. Just for a little bit of clarity before we go any further both classes were referred to as Jinty’s or Jocko’s so going forward, if I mention Jinty’s I mean the later LMS Fowler 3f.

So the 2441 class. The Midland built 60 of these which were considered as heavy goods tank engines. They were later rebuilt by Fowler which made them look very similar indeed to a Jinty. Initially there were 2 distinct types. with or without condensing apparatus. For those interested in these locos theres a good book on the subject, Midlands Engines No.5 by David Hunt, Bob Essery and Fred James (ISBN 1-874103-94-1)

The Model

Work required can be broken down into 2 areas. Stuff you might want to do anyway and stuff you will need to do to depict the 2441 class. Let’s start with the stuff you might want to do anyway.

The handrails need replacing as do the lamp irons. The Chimney is a bit naff as are the safety valves and whistle. The coal rail is too chunky and the buffers are somewhat generic. The steps would benefit from something a little more refined.

For the 2441 specific bits the smokebox needs to be shortened and its saddle is a different shape. The Dome is also a different shape (more rounded) although I believe some had the more flattened off type. The front splashers are different too. The biggie is the tank sides which are taller and drop down by the cab area to be a little lower than a Jinty. The bunker is also lower and squarer with no overhang. The footplate is actually a little longer on these locos and the fairing at the ends is different.

So let’s start with the footplate. The body of the model separates into 3 parts. The footplate, tank sides and bunker. The boiler, smokebox and tank tops and the upper part of the cab. Handily everything is plastic so carving it up is easy. I believe that the Bachmann Jinty has a cast metal footplate so it might be a bit more tricky.

So let’s start with the footplate. The body of the model separates into 3 parts. The footplate, tank sides and bunker. The boiler, smokebox and tank tops and the upper part of the cab. Handily everything is plastic so carving it up is easy. I believe that the Bachmann Jinty has a cast metal footplate so it might be a bit more tricky.

The tank sides and bunker are from 30thou plasticard topped with microstrip. The coal rails come from my spares box (Brassmasters 1f etch) and the steps are from Mainly Trains. Splashers are also from Brassmasters (1f again) and the buffers and vac pipes are from Lanarkshire models. The lamp irons are from Stenson models. You can see at the back of the footplate where it’s been lengthened.

Not a lot to do the cab. New rear spectacle plates from Mainly trains.

Not a lot to do the cab. New rear spectacle plates from Mainly trains.

The Boiler. I cut the smokebox back and remounted the front piece (which is separate). It seems that the condenser fitted locos had the handrail below the upper hinge like a Jinty but the others has it mounted above the hinge. Chimney is from my spares box (Brassmasters Jinty detailing kit I think) and the safety valves and whistles are from Markits. The top of the dome had been filled and blended into a new shape.

The Boiler. I cut the smokebox back and remounted the front piece (which is separate). It seems that the condenser fitted locos had the handrail below the upper hinge like a Jinty but the others has it mounted above the hinge. Chimney is from my spares box (Brassmasters Jinty detailing kit I think) and the safety valves and whistles are from Markits. The top of the dome had been filled and blended into a new shape.

When it comes to the tank tops, the drawings show the filler caps to be more central and they certainly would need to be on the condensing locos as theres a big pipe in the way. However pictures of the non condensing ones show what looks like the bracket at the front of the tank indicating that they might be at the front as seen on the model.

A little bit of fiddlyness for the ejectors. The moulded one is a bit clunky and I believe depicts a combined large and small Ejector. When I did my other Jinty I used a cast detailing part for this from (I think) London Road Models. Some 2441 class locos had these. The fiddly one depicts an earlier type and is cobbled together from 0.4mm wire with 0.6 and 0.8mm tubing.

A little bit of fiddlyness for the ejectors. The moulded one is a bit clunky and I believe depicts a combined large and small Ejector. When I did my other Jinty I used a cast detailing part for this from (I think) London Road Models. Some 2441 class locos had these. The fiddly one depicts an earlier type and is cobbled together from 0.4mm wire with 0.6 and 0.8mm tubing.

The assembled loco (so far) The chassis is a High level Jinty with the frames altered to be shallower. Otherwise it’s built as per the kit. I didn’t go for working inside motion as you really cant see it at all on these locos.

The assembled loco (so far) The chassis is a High level Jinty with the frames altered to be shallower. Otherwise it’s built as per the kit. I didn’t go for working inside motion as you really cant see it at all on these locos.

Steel and Glass

Let’s talk about glass. Something Stourbridge is particularly renowned for. It is believed that there has been glass production in the area for hundreds of years with a factory opening at the lower end of what is now Brettell Lane in the 1640s and production continuing in the area ever since.

You’re going to need your imagination for this bit! Regular readers will know that Brettell Road is not an accurate model of the real Brettell lane but is inspired by it and the local area. The above picture taken in August 2014 (that long already?) shows what was left of the goods yard at Moor Lane. Brettell Lane is behind us. The line to Pensnett branched off on the left and the yard is petty much straight ahead of us. You can see the flood lights against the skyline. This was the view from the left hand end of the original version of Brettell Road and is now the view from the middle looking to the right. On the model the line is not an S curve but a continuous left hand bend. Also the main line descends from this point on the layout while the real line rises as it goes away from us.

You’re going to need your imagination for this bit! Regular readers will know that Brettell Road is not an accurate model of the real Brettell lane but is inspired by it and the local area. The above picture taken in August 2014 (that long already?) shows what was left of the goods yard at Moor Lane. Brettell Lane is behind us. The line to Pensnett branched off on the left and the yard is petty much straight ahead of us. You can see the flood lights against the skyline. This was the view from the left hand end of the original version of Brettell Road and is now the view from the middle looking to the right. On the model the line is not an S curve but a continuous left hand bend. Also the main line descends from this point on the layout while the real line rises as it goes away from us.

On the right, long gone now, there used to be a siding which served the Brierley Hill glassworks. The buildings are still there and can just be seen behind the trees in the distance where the mainline disappears.

Another view from 2014 that shows the building being converted into apartments. If you stand looking at the right hand end of the layout you would effectively be standing in this building. The line runs behind it and you can just make out the ironwork of Moor Lane Bridge on the right of the picture above the yellow van. This building is represented on the layout as part of the backscene.

Another view from 2014 that shows the building being converted into apartments. If you stand looking at the right hand end of the layout you would effectively be standing in this building. The line runs behind it and you can just make out the ironwork of Moor Lane Bridge on the right of the picture above the yellow van. This building is represented on the layout as part of the backscene.

Brierley Hill glass was more of the decorative, cut glass and crystal type than the industrial large sheets and I have a few shockvans as a nod to glass traffic but of course they could be carrying anything so only I know that. However thanks to a gift from my friend Tom i now have something a little more obvious…

I present you the ancient K’s kit for the GWR Coral glass wagon. These were built in 1908, to 2 diagrams, by Swindon to carry large plate glass in crates. BR briefly continued with these building 6 more examples before switching to the LMS design but even then only building 42 wagons (also at Swindon).

I present you the ancient K’s kit for the GWR Coral glass wagon. These were built in 1908, to 2 diagrams, by Swindon to carry large plate glass in crates. BR briefly continued with these building 6 more examples before switching to the LMS design but even then only building 42 wagons (also at Swindon).

I decided to build one of the BR types with the main differences being (as far as i can tell) the shape of the ends of the frames, the GWR ones being more curvy, and the brake levers. The model had been started by Tom’s dad but was dunked in some cellulose thinners which dissolved the glue (but not the paint strangely) before it was reassembled using low melt solder. The kit had some nice brass buffers which were replaced with Lanarkshire models which better match the BR examples. The upper frames were cast in whitemetal and there were only 2 of them so they were replaced with brass section. A part of the original casting was soldered to the end of the underframe and reshaped to better match the BR design. I used the slotted bearing and central pivot method of compensation as previously used on my lowmac.  In service on the layout. As mentioned its not really the sort of glass that Brierley Hill was known for but it is a nod to the industry. Apparently some of the real wagons were transferred to the steel industry anyway so perhaps its on trial in the area for that reason instead?

In service on the layout. As mentioned its not really the sort of glass that Brierley Hill was known for but it is a nod to the industry. Apparently some of the real wagons were transferred to the steel industry anyway so perhaps its on trial in the area for that reason instead?

Thanks go to Tom and his dad.

A couple of classics

This time we have a couple of classics from the Cambrian range

The good old catfish. Built with the use of Stenson models hand wheels and replacement handrails. One thing with these, as supplied, is that the wheels seem a long way away from the w W-irons, even in P4 so I cut the moulded rings off the back and moved the solebars closer together. A lot of people say these are a bit tricky but the only real difference to any other kit is you just need to take a lot longer and really let things set. They aren’t really a bung it together in an afternoon style job. I found another 2 kits in my stash which i will build up for New Street and might do a bit of a step by step on how to do them.

The good old catfish. Built with the use of Stenson models hand wheels and replacement handrails. One thing with these, as supplied, is that the wheels seem a long way away from the w W-irons, even in P4 so I cut the moulded rings off the back and moved the solebars closer together. A lot of people say these are a bit tricky but the only real difference to any other kit is you just need to take a lot longer and really let things set. They aren’t really a bung it together in an afternoon style job. I found another 2 kits in my stash which i will build up for New Street and might do a bit of a step by step on how to do them.

Next up the mermaid. I have built this as an early one which were the same as the original GWR builds. The main difference is push rod brakes instead of clasp, no vacuum brakes and earlier buffers. The rail clamps were replaced with Roxey mouldings shackles.

Next up the mermaid. I have built this as an early one which were the same as the original GWR builds. The main difference is push rod brakes instead of clasp, no vacuum brakes and earlier buffers. The rail clamps were replaced with Roxey mouldings shackles.

Below – It seems Brettell Road has had something of a GWR take over today!

LMS iron ore hopper

Let’s start with a little observation. Modelling railways is expensive these days, the reason for this has been discussed elsewhere but if I were starting out now I certainly wouldn’t be able to afford it. I actually think the prices are what they are but there are one or 2 things where manufacturers really are taking the mick.

Case in point is the 24ton LMS iron ore hopper. Firstly its not one, at all! Basically yes it is a hopper but thats about it. It’s a loose model of the Charles Roberts hopper with a body stretched to fit a generic 10ft chassis. When you consider that this model first appeared in the 1977-78 mainline railways catalogue charging nearly £30 rrp for a completely wrong, very old tooled model is a fictitious livery is more than a little bit dodgy, Considering thousands of these are out there in various liveries for a fraction of the price you have to wonder who’s actually buying the things?

So let’s look at what this model attempts to be.

LMS hoppers are something of a gap in the RTR market as they have been hardly touched by either RTR or kit manufactures. I believe that the model is trying to masquerade as a diagram 1893-1942 iron ore hopper. From what i can tell these were all the same except for the materials used.

D1893 – 50 wagons built in 1934 by the Metropolitan Carriage, Wagon and Finance Company out of Chromador Steel

D1894 – 300 wagons built in 1934 by the trade out of mild steel

D1941 – 450 wagons built in 1936-38 by the trade out of copper bearing steel

D1942 – 100 wagons built in 1936 by the Gloucester Carriage and Wagon company out of an unspecified material.

Many of these lasted into the BR era and were cascaded to various steel works meaning theres quite a few liveries that can be done and an enterprising manufacturer can cash in on the current rise of interest in industrial modelling.

The model

While the RTR hoppers wheelbase of 10 ft is actually closer to the LMS wagons 10ft 6 than it is the Charles Roberts 9ft wheelbase theres nothing about the model that can really give you ahead start on constructing one of these so the easiest method is just to scratch-build one.

Which is what I did. Construction is plasticard with evergreen sections for the chassis and rivet strips from Mainly Trains or transfers from Archers. Buffers are from Lanarkshire models and underframe ironwork from Ambis and Bill Bedford. The axleguards, axle boxes and springs are salvaged from parkside kits. Drawings in LMS wagons volume 1 were used as a guide.

Which is what I did. Construction is plasticard with evergreen sections for the chassis and rivet strips from Mainly Trains or transfers from Archers. Buffers are from Lanarkshire models and underframe ironwork from Ambis and Bill Bedford. The axleguards, axle boxes and springs are salvaged from parkside kits. Drawings in LMS wagons volume 1 were used as a guide.

Painted up with transfers from Modelmaster and Fox.

Painted up with transfers from Modelmaster and Fox.

Comparison with the Charles Roberts wagon on the right. This has been shortened and rebuilt on a 9ft chassis so its not a direct comparison with the RTR model as supplied. To see what I did to that one click here)

Comparison with the Charles Roberts wagon on the right. This has been shortened and rebuilt on a 9ft chassis so its not a direct comparison with the RTR model as supplied. To see what I did to that one click here)

An unremarkable little tank engine – Part 2

Thoughts turn to the remaining detailing on the body of my 57xx tank. I like to take pictures pre paint for prosperity before it all disappears under plain black and grime and no one really notices what you’ve done anymore!

Front 3 quarter view. You will notice that the buffers are different. Due to a timely new casting arriving from Lanarkshire models. Lamp irons are from Masokits and the sanding levers from RT models.

Front 3 quarter view. You will notice that the buffers are different. Due to a timely new casting arriving from Lanarkshire models. Lamp irons are from Masokits and the sanding levers from RT models.  The footplate pipework has been replaced with wire The Whistle shield is from Modelu reinforced with a bit of wire. The tool box seemed a little ‘floaty’ as mainline had modelled it so I filled in the gap and re-scribed a finer one.

The footplate pipework has been replaced with wire The Whistle shield is from Modelu reinforced with a bit of wire. The tool box seemed a little ‘floaty’ as mainline had modelled it so I filled in the gap and re-scribed a finer one.

Rear view. The fire irons are from Springside Models and the rear windows from Mainly Trains (now Wizard models). I’ve thinned down the cab sides

Rear view. The fire irons are from Springside Models and the rear windows from Mainly Trains (now Wizard models). I’ve thinned down the cab sides  I tried to do the water balancing pipe as one piece secured by magnets but as its all a little bit small the magnets weren’t really strong enough. I had fears of it falling off and causing havoc with the inside motion so I had to settle for it being in 3 parts instead. Not sure what the little box is behind the rear footstep not all locos had them. I think it might be related to the AWS gear.

I tried to do the water balancing pipe as one piece secured by magnets but as its all a little bit small the magnets weren’t really strong enough. I had fears of it falling off and causing havoc with the inside motion so I had to settle for it being in 3 parts instead. Not sure what the little box is behind the rear footstep not all locos had them. I think it might be related to the AWS gear.

Underside view – you can just make out the way the pickups are arranged.

My intended victim for this model was 8718 which in Brettell Lane era was a Kidderminster Loco. It later went to Stourbridge where it lost its number plates and gained painted on numbers in a reasonable attempt at the GWR font. I preferred the proper number plate. Searching for pictures I couldn’t make out a BR logo on the tank sides. A request to the GWR modellers and British Railways Steam era 1948 to 1968 facebook groups didn’t yield any answers either so reverting to my ‘model what you see, not what you think you know’ approach I left the logo off.

Below a few images of the finished loco. The crew are the customary Modelu products.

So there you have it – An unremarkable little tank engine.

An unremarkable little tank engine – Part 1

One of my slow burning projects has been a humble little 57xx tank. A combination of the old (But essentially quite good) Mainline body and a High Level Kits chassis but with a bit of twist.

Iain Rice wrote about these back in MRJ 61 and 62 using a similar route, in his case using a Perseverance chassis as that was what was available around the time, and I would urge readers to refer to this as a start point.

The High Level chassis

Like all of Chris’ chassis this was a joy to build (this is my 4th of his chassis kits now, who would have thought it?) I opted to use Brassmasters bearings which may have messed the alignment up a little as I found I needed to mount the break gear 1 mm lower than as supplied. Strangely though the buffer height seems fine. I differed a little bit from the instructions by making all of the brake gear removable. The rear rods that go behind the wheels seems to trap the rear axle in place as supplied.

Like all of Chris’ chassis this was a joy to build (this is my 4th of his chassis kits now, who would have thought it?) I opted to use Brassmasters bearings which may have messed the alignment up a little as I found I needed to mount the break gear 1 mm lower than as supplied. Strangely though the buffer height seems fine. I differed a little bit from the instructions by making all of the brake gear removable. The rear rods that go behind the wheels seems to trap the rear axle in place as supplied.

Eagle eyed viewers might spot something little odd and yes, you’ve guessed it – I’ve gone off piste again.

A couple of prototype pics from the Severn Valley. Personally i though the inside motion was pretty obvious looking at the real thing and while there is a representation of it in the High Level Kit I wanted it to move.

A couple of prototype pics from the Severn Valley. Personally i though the inside motion was pretty obvious looking at the real thing and while there is a representation of it in the High Level Kit I wanted it to move.

So this is a mish mash of bits – Brassmasters 4f bits at the axle end and Finney GW bits at the front. The GWR version of inside motion seems much simpler that the midland one and the hardest part of this task wasn’t putting it all together but getting it in place. Being a small loco theres not a huge amount of wiggle room.

So this is a mish mash of bits – Brassmasters 4f bits at the axle end and Finney GW bits at the front. The GWR version of inside motion seems much simpler that the midland one and the hardest part of this task wasn’t putting it all together but getting it in place. Being a small loco theres not a huge amount of wiggle room.

The body is essentially good, you could say extremely good for its time. The obvious stand out bit of weirdness was the top of the dome but nothing a spot of filing can’t sort out. It did come with a separate main handrail and some wire ones around the bunker but they were all a bit heavy so i replaced those along with those handrails that were moulded on. I reduced the size of the front wheel splasher by cutting it off and gluing it back on, The width of the cut being all you really need. I didn’t feel the need to fiddle with the centre and rear ones. While on my 94xx I replaced all the pipework under the tanks in front of the cab with this model I thought it was good enough as is, although I have cut away the ‘holes’ as per Iain’s article. Theres a bit more detailing to add to the footplate yet and the lower pipework will need to be replaced.